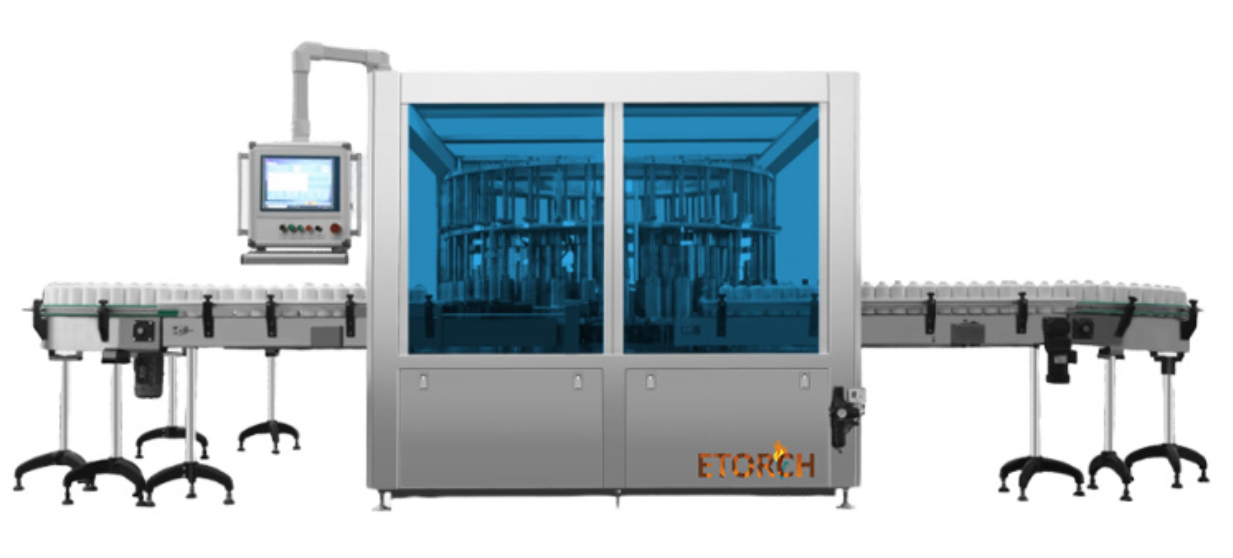

Light Inspection and Leakage Detection Machine

BRIEF INTRODUCTION

Standalone Positioning

Independently completes appearance inspection, visible foreign matter inspection, and leak detection, fully meeting GMP requirements for standalone production.

Applicable Packaging & Specifications

Packaging Types: Vials / Ampoules

Filling Volume Range: 1 – 20 mL

Throughput: 36,000 containers/hour

(Verified under 2 mL ampoule, aqueous solution conditions)

Process Flow

Container Infeed → Integrated Processes of This Unit: Surface Inspection → Internal Inspection → Leak Detection → Qualified Discharge / Reject Separation

Key Performance Parameters

Construction & GMP Design

304 stainless steel and anodized aluminum frame, surface finish Ra ≤0.8 μm.

Upper–lower separation between inspection zone and drive zone, ensuring easy cleaning and no cross-contamination.

Quick-release rotating container holders made of POM + ceramic inserts, with no exposed lubrication.

Control System

Dual industrial PCs (Windows 10) + Siemens PLC, with three-level user access management.

Automatic batch report generation with USB/PDF export.

OPC UA interface reserved for seamless integration with MES / LIMS.

Utility Requirements

Automatic Lyophilized Vial Inspection Machine

Automatic Impurity & Leak Inspection Machine

Ampoule automatic leakage detection machine

Bottle automatic leakage detection machine

我们的产品

GIVE US A MESSAGE